Making more than just sails, this historic Greenport business is an insider resource for all things canvas.

Making more than just sails, this historic Greenport business is an insider resource for all things canvas.

The battered sign hanging on the far wall of the Wm. J. Mills and Co. Sailmakers showroom shows its age. ‘Established 1880’ it says, the year an enterprising Scottish immigrant named William Mills hung this very shingle outside his freshly-minted workshop in Greenport, which in those years was a commercial fishing hub. Mills quickly distinguished himself for the quality of his work and his sails were much in demand throughout the eastern seaboard. Among his workshop’s most prestigious commissions were a speed pennant for the steamship the SS United States, which crossed the Atlantic at record speed; sails for the USS Constitution, the 44-gun wooden-hulled three mast frigate of the US Navy; and custom-canvas for those sturdy unsinkable fishing boats called Boston Whalers. (From 1960 to 1996, Mills was the Whalers’ sole canvas supplier).

Housed since 1986 in a 15,000 square foot facility just outside the village, the business has grown to encompass far more than sails. In fact, says co-proprietor Robert L. Mills II, the great-grandson of the founder, sail making represents but a small part of the company’s activities. Sure, they’ll make a sail for your boat and a good one–Robert Mills, who took his first solo voyage in Hallock Bay, on the northeast edge of Orient Harbor, aged five, is the head sail designer–and their sail loft, where the sails are laid out, is among the biggest on the East End of Long Island—but they also fabricate custom canvas marine products and awnings and such free-standing canvas structures as canopies, shower enclosures, and covers for outdoor kitchens.

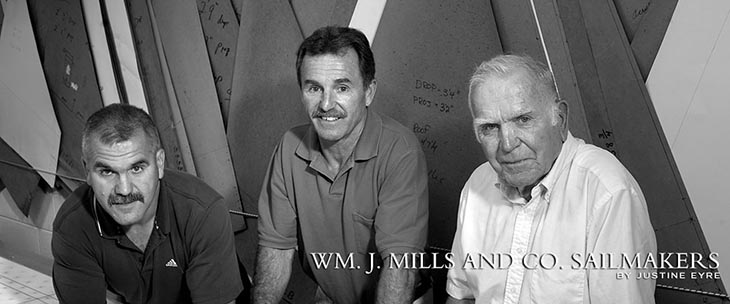

Bob and his brother, William J. Mills III run the company with practical advice from their not-quite-retired ninety three-year-old father, William J. Mills II. (The latter still comes into work every day). As children, Bob says, the Mills brothers could tie bowlines behind their backs in under four seconds, but they had to wait until their eleventh year to join the family business when they were entrusted with emptying the rubbish bins. Today the two oversee some twenty employees, the longest serving of whom is Greenport native Gil Raynor, who on a recent afternoon was cutting canvas on a long table. Raynor began as a young apprentice (“Still an apprentice,” he notes. “Just starting to get the hang of it.”) It was around the time, Raynor says dryly, that Columbus and his men arrived in the Americas. (“That would be I967,’” Bob Mills clarifies.)

Mills estimates that while the life span of a canvas awning is ten years, a good frame can last forever. Elizabeth Thompson, an architect with offices in Orient and New York City, has commissioned custom awnings and sunshades from the company, some of them of quite complex design. “They always get the work done on time and I’ve never had any of their products wear out,” she says. And for good reason. As Mills notes, “We overbuild everything. Over the years, we’ve recovered awning frames that I installed when I was in my teens. As I always say, ‘I’m a man of the cloth.’”